Safety is a big deal.

Any chainsaw can cause injuries. But the bigger the saw, the more powerful is, the larger and sharper the chain is, risks go up.

The more cutting I do, the more injuries I see. Part of that is just people being careless. Part of it is just people getting tired. Spending all day wrangling trees, limbs, brush, and a heavy saw can wear you out. The more fatigue sets in, the more likely you are to get careless, sloppy, forgetful, and BAM! an accident happens.

To each his own, but I am a big believer in buying the right safety gear. I work hard for a living, and I don’t have time to lay around in a hospital bed or on a couch somewhere with my leg propped up oozing puss. I’m not trying to be gross here, just blunt. I need to stay healthy and productive so I can pay the bills.

When I heard about Husqvarna’s safety kit, I jumped on the chance to buy one, try it out, and provide a review for you guys. They market this towards “landowners”. After asking around, I came to the conclusion they just mean it’s not really meant for professionals who do this for a living, day in and day out, all day long.

What is it, and what’s included?

Husqvarna part number 531300904 is their Chainsaw Protective Apparel kit. It includes the following items:

- ProForest woodsman hi-viz helmet

- Xtreme duty work gloves

- Blue clip suspenders

- Apron chaps

- Lexan clear protective glasses

- Lanyard for the glasses

How’s the quality?

I will step through each component of the kit and review with you what I think…

Suspenders

Let me start off by saying I don’t care if it makes me look like a grumpy old man, I prefer to wear suspenders when I’m using a chainsaw.

Why are suspenders safety apparel, you ask?

Why are suspenders safety apparel, you ask?

About the time you get geared up and you’re sawing like a madman, you will be hot and sweaty, and your pants will start to fall off.

Who wants to drop the saw, take their gloves off, and hitch up their pants?? Nobody, that’s who. And especially when you have to do that every five minutes, it’s hard to get anything done.

Doing that one-handed, trying to keep a chainsaw balanced on a limb while you keep your pants from falling down and exposing the south forty with your other hand – that’s just not safe.

Yes, you can wear a belt. But when I get sweaty, the belt tends to absorb perspiration and stretch, which is just a recipe for droopy pants. Suspenders are the perfect solution to that. There is a reason you see so many pro chainsaw users wearing suspenders. There is a reason Husqvarna includes suspenders in this kit. Because they work, period.

These are great suspenders. The clips don’t give up or slip off. They are fully adjustable, and once adjusted they won’t slip or slide. They are plenty wide and solid feeling. If you carry as much crap in your pants pockets as I do, your pants can get heavy, and you don’t want a little pair of shoestring suspenders struggling to handle the stress.

These suspenders are made for men, who are doing a man’s job, and need a man’s equipment. If I had three thumbs I would give them three thumbs up, that’s how much I endorse them!

ProForest Woodsman Hi Viz Helmet

If I had to guess, I would say Husqvarna has the market cornered on chainsaw helmets.

If you aren’t a professional lumberjack, you may think you can get away with not wearing a helmet. And you may be right. But it’s not just protecting your noggin that is this helmet’s main claim to fame.

If you aren’t a professional lumberjack, you may think you can get away with not wearing a helmet. And you may be right. But it’s not just protecting your noggin that is this helmet’s main claim to fame.

There are three other hidden little gems associated with this helmet, and I’m going to give you the scoop right here on ChainsawsToday.

Integrated into the helmet are ear muffs for hearing protection. There are some battery and corded chainsaws out there that are quiet enough that they don’t require hearing protection. The Greenworks 20312 comes to mind. But unless you have made the jump to battery, it’s an absolute necessity that you wear muffs.

These are 25 dB muffs, so they do a good job of keeping the noisiest of big, powerful saws down to a manageable level.

The second feature is the full-face visor. We’ll get to the glasses here in a minute, I’m talking about the large mesh visor on the front of the helmet. This thing is awesome. Regardless of whether you are wearing safety glasses (and you should be), invariably you stand a chance of kicking something up into your eyes. I couldn’t tell you how often this has happened to me. Debris tends to bounce up under the edge of safety glasses, or fall down between my eyebrows and the top edge of the glasses.

Well this visor stops it from happening!

Also, branches tend to whip around when you are working hard, and it usually doesn’t feel good when they slap you in the face. I’ve even had safety glasses knocked off my face, and I’ve seen a guy get busted in the nose before.

Now obviously this visor isn’t meant to stop a punch or block a brick. The mesh material is actually a bit flimsy, by design. But if and when it gets damaged, it is easily replaced, and Husqvarna sells replacement shields. And it’s ingenious when compared to a clear plexiglass shield, since we all know that would get scratched up before long and be difficult to see out of.

What the visor does well is keep sawdust from flying up under your glasses, or bouncing into your mouth and down your neck/collar. If you were wondering, the visor can be flipped up out of the way when you are inbetween cuts.

Hold on, I’m not done yet.

The third feature is the the little shield you see above the visor on the front of the helmet. This is a sun and rain shield. And it’s awesome.

Yes, it sucks if you have to work in a downpour or in the sweltering sun. It’s not like some magic guarding is going to stand behind you and hold an umbrella. You would be surprised at how much of a difference this little swoop of a shield makes.

Now it’s not very big, granted. Sometimes I had to angle my head a bit in order to have it properly shield my eyes from a rising or setting sun. But the fact that it’s there is really handy, and having used it I wouldn’t buy one without the feature.

Getting back to my original statement, it’s perfect that these three features are integrated into the helmet. Instead of having to store and put on all of these different elements, they are all strapped together and ready to go. That means you don’t have to chase them all over the cab of your truck, or try to find them in the bottom of your toolbox.

Xtreme Duty Work Gloves

If you’ve seen my chainsaw gloves review, you already know that I’m picky about my gloves.

If you’ve seen my chainsaw gloves review, you already know that I’m picky about my gloves.

Husqvarna’s Xtreme Duty gloves weren’t included in my review for one simple reason: they market them as work gloves vs chainsaw gloves. Now that doesn’t mean they can’t be used in chainsaw applications, and obviously Husqvarna has chosen to include them in this kit.

They are double-reinforced in some (high wear) areas, and they have an elastic wrist to keep them snug and in place.

These are good gloves – they fit well and they seem to wear well. I think they would’ve placed mid-pack in my previous review. I like them, and I think they make sense as a part of this kit, but I think I like the Husqvarna Chainsaw gloves slightly better.

Apron Chaps

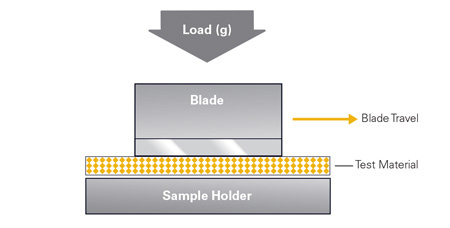

Husqvarna’s apron chaps are designed with a series of straps and buckles to wrap securely around your waist and legs. The material is described as polyester with a PVC coating, and was developed to try and shield you from a spinning chain if accidental contact is made.

Husqvarna’s apron chaps are designed with a series of straps and buckles to wrap securely around your waist and legs. The material is described as polyester with a PVC coating, and was developed to try and shield you from a spinning chain if accidental contact is made.

These things get really great reviews online. Some people have even posted photos of how the chaps ripped (in a sacrificial way) to save the operator from a chainsaw. People seem to be fiercely loyal to this brand and these specific chaps.

I really like them. They are a little pricier than some other chaps that are on the market, but this doesn’t seem like a good place to skimp on a few pennies. The only real drawback here is they can be hot. If you’re using them in particularly hot weather, they are just going to make you that much more miserable. But probably any pair of chaps is going to do that.

I really like them. They are a little pricier than some other chaps that are on the market, but this doesn’t seem like a good place to skimp on a few pennies. The only real drawback here is they can be hot. If you’re using them in particularly hot weather, they are just going to make you that much more miserable. But probably any pair of chaps is going to do that.

I will also point out that although they have their limitations, wearing some “armor-plated” chaps like these really lends me a sense of security. I guess it’s like a football player putting his pads on. Of course you can still get hurt, but getting outfitted up puts me in a serious frame of mind where I’m ready to get some work done while avoiding injury.

Safety Glasses

Some would say these are redundant if you’re wearing the helmet with the visor. But I’ve already covered that argument above.

Some would say these are redundant if you’re wearing the helmet with the visor. But I’ve already covered that argument above.

You need to wear safety glasses when you’re operating a saw, and these fit the bill. They don’t blink neon lights, or tie your shoes, or sing piano bar tunes. They aren’t exciting, in other words. But they get the job done.

It’s nice that Husqvarna throws in the branded lanyard for the kit. I have a tendency to set things down when I’m refueling or taking a break, and it can be hard to find if you’re in the middle of the forest with lots of undergrowth. The lanyard keeps them around your neck where you can find them.

Recommendation

Convenience is king, and Husqvarna wins the prize with this “all-in-one” protective apparel kit. The glasses and the gloves are fine, but it’s the helmet and the chaps that seal the deal.

You should buy this kit, no questions asked. If you want to piecemeal the elements together, that’s fine, but I don’t know why you’d go through the trouble. Even if you already have chaps, or a helmet, or any of these pieces, I’m willing to bet your stuff is either worn out or soon will be. To me, it’s easy and it makes sense to order one box and get everything you need!

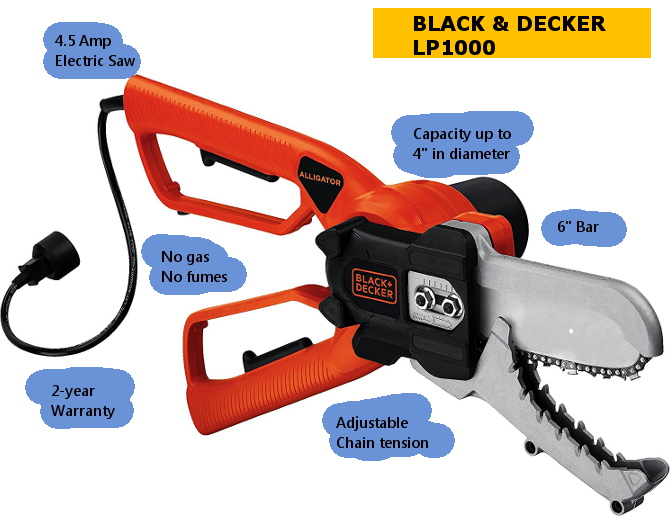

Even though this thing feels like a featherweight, it feels solid. The box says it’s only 10.4 lbs, and my lower back corroborates that story.

Even though this thing feels like a featherweight, it feels solid. The box says it’s only 10.4 lbs, and my lower back corroborates that story. It feels plenty powerful. Of course with it being brand new and having a sharp chain, I was pretty impressed with how it slices through pretty much anything.

It feels plenty powerful. Of course with it being brand new and having a sharp chain, I was pretty impressed with how it slices through pretty much anything.

And the Greenworks has a 40v 4.0Ah battery, while the Black & Decker has a 40V 2.0Ah.

And the Greenworks has a 40v 4.0Ah battery, while the Black & Decker has a 40V 2.0Ah.

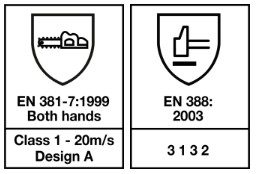

Too many casual chainsaw users make the mistake of thinking safety gear isn’t important. I wanted to make a post about the 10 best chainsaw gloves on the market in 2018 specifically to draw attention to this topic.

Too many casual chainsaw users make the mistake of thinking safety gear isn’t important. I wanted to make a post about the 10 best chainsaw gloves on the market in 2018 specifically to draw attention to this topic. This surprised me. Most of the guys I know who use a chainsaw, either casually or even for a living, tend to be what I would consider to be “macho men”. Not a group that I would think is overly concerned about how a pair of gloves look.

This surprised me. Most of the guys I know who use a chainsaw, either casually or even for a living, tend to be what I would consider to be “macho men”. Not a group that I would think is overly concerned about how a pair of gloves look. I think chainsaw gloves need some element of abrasion resistance, as well as some element of cut resistance.

I think chainsaw gloves need some element of abrasion resistance, as well as some element of cut resistance. It’s great to protect our hands, but if you’re like me you hate that you lose so much of the tactile feel you need to do a job well when you wear gloves.

It’s great to protect our hands, but if you’re like me you hate that you lose so much of the tactile feel you need to do a job well when you wear gloves. I would rank cost as a factor. I guess everyone’s budget is a little different. I tend to be frugal, but maybe less so when it comes to safety gear.

I would rank cost as a factor. I guess everyone’s budget is a little different. I tend to be frugal, but maybe less so when it comes to safety gear.

I tried these out with my chainsaw, and honestly I don’t think I can recommend them. They are just too slippery. They are fairly inexpensive, so if you want to give them a try, I don’t think you will be out much money.

I tried these out with my chainsaw, and honestly I don’t think I can recommend them. They are just too slippery. They are fairly inexpensive, so if you want to give them a try, I don’t think you will be out much money.