I was recently hired to do some brush and tree maintenance on a trail.

The trail is three miles long. It starts at a public parking lot here in my hometown, and winds its way up through some pretty rough country.

Much of the trail is not accessible by any type of motorized vehicle.

Much of the trail is not accessible by any type of motorized vehicle.

The city hired me to cut down some risky trees, saw up and clear some previously fallen trees, and clear away any brush that was closing in on the trail.

This took me several weeks. Although it was quite a bit of work, I found it really enjoyable.

This was the first time I’ve tackled a job like this. I learned so much!

A few lessons I’ll share with you…

1) You can never have too much water. Well, okay, if you took a zillion gallons and the weight was more than you could carry, of course that would be too much. My point here is doing all that hard work will make you sweat, and you are going to need to hydrate.

1) You can never have too much water. Well, okay, if you took a zillion gallons and the weight was more than you could carry, of course that would be too much. My point here is doing all that hard work will make you sweat, and you are going to need to hydrate.

2) A saw that’s too big is not ideal for this type of job. Using more fuel than you need is a terrible idea if you have to backpack in all of your supplies. I used a small 16″ Husqvarna saw to keep things light and make fuel use manageable. I’ll have to remember to review the saw for you sometime.

2) A saw that’s too big is not ideal for this type of job. Using more fuel than you need is a terrible idea if you have to backpack in all of your supplies. I used a small 16″ Husqvarna saw to keep things light and make fuel use manageable. I’ll have to remember to review the saw for you sometime.

3) Pack some toilet paper. I don’t want to get too personal here, but in some cases I was an hour or hour and a half walk from the truck. At even then, I would have to drive to a nearby gas station or store to find a bathroom. That’s not going to work, guys! I packed some TP, and when I had to go I did so behind a tree.

3) Pack some toilet paper. I don’t want to get too personal here, but in some cases I was an hour or hour and a half walk from the truck. At even then, I would have to drive to a nearby gas station or store to find a bathroom. That’s not going to work, guys! I packed some TP, and when I had to go I did so behind a tree.

One piece of equipment that I found very hand for this type of work is a chainsaw backpack.

I guess they are a bit of a niche product, made popular by firefighters who have to carry their chainsaws for long distances.

If you have a big piece of property or a trail that is not accessible by vehicle or even UTV, this type of carrying solution is exactly what you need.

True North Chainsaw Backpack – Review

I purchased this knowing that carrying my chainsaw, fuel, water, and axe was going to be very difficult towards the back side of the trail (3 miles away from my truck).

Although it is a solid piece of equipment, the True North pack is not overly heavy. It weighs in at just 5.5 lbs.

The straps and pouches are made from nylon webbing and a type of extreme-duty synthetic material.

The pack has shoulder straps as well as a waist strap. They are double-padded thick, and the thing is fairly comfortable. I mean, you are strapping a bunch of heavy stuff to your back, so it’s not like taking a nap on your couch, but they have really thought the design through for both comfort and strength.

This thing is pretty much everything-proof. I sweated on it, drug it through heavy branches and briar patches, and tossed it in the back of my truck bed.

I guess one criticism is the heavy duty material is pretty rough, and tends to collect mud and debris. I actually used a garden hose and a soft bristled brush to clean my periodically.

They don’t list a weight capacity, but I figured my back would probably give out before this pack would!

They don’t list a weight capacity, but I figured my back would probably give out before this pack would!

It has 3 pouches – one for fuel, one for water, and one for miscellaneous. It also has an axe scabbard.

There is a leather reinforcement on top of one of the straps which protects the strap when you carry your saw or a big nasty piece of wood on your shoulder. I thought that was a pretty innovative feature.

It is basically one size fits all. All of the straps are adjustable. I’m a pretty bulky guy, and it fit me just fine. Maybe if you’re more than 300 lbs or less than 100 lbs it could give you some trouble, but outside of that it was just the right size.

It is basically one size fits all. All of the straps are adjustable. I’m a pretty bulky guy, and it fit me just fine. Maybe if you’re more than 300 lbs or less than 100 lbs it could give you some trouble, but outside of that it was just the right size.

I used True North’s chainsaw backpack for a solid two weeks.

I walked somewhere in the neighborhood of 100 miles with it fully loaded on my back.

I put it on and took it off dozens of times per day, and never once did I take it easy on it or give it a break.

I think True North developed this specifically for commercial firefighters who needed a dependable, fool proof way to backpack their saws over rough terrain… and it shows.

If you’re in the market for something like this, I don’t think you can go wrong with their product!

These days I stay pretty busy as a local handyman.

These days I stay pretty busy as a local handyman. The local hardware place wanted $60 per day to rent out a cement mixer. I thought it would take me probably a day and a half, and when you look at transport time and cost, it was going to cost me right at $150 to rent one. It was apparently I could buy an inexpensive one for not much more than that, so I pulled the trigger!

The local hardware place wanted $60 per day to rent out a cement mixer. I thought it would take me probably a day and a half, and when you look at transport time and cost, it was going to cost me right at $150 to rent one. It was apparently I could buy an inexpensive one for not much more than that, so I pulled the trigger!

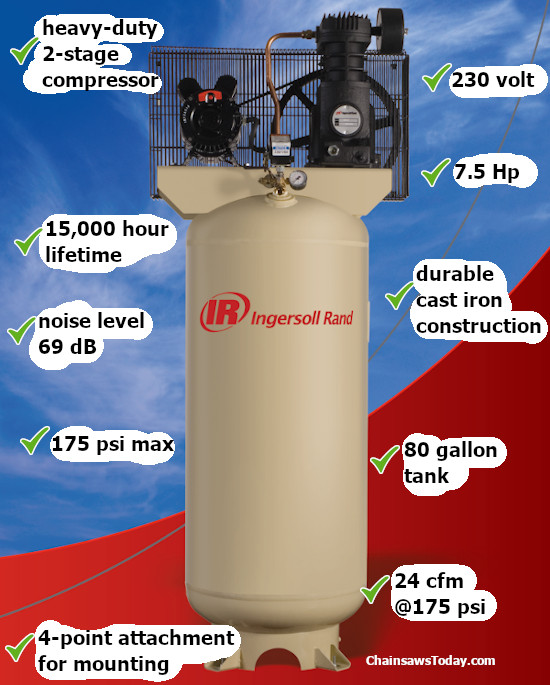

My twenty year old air compressor finally gave up the ghost.

My twenty year old air compressor finally gave up the ghost. The “gallon” refers to the size of the tank. This is like a battery. The bigger the volume of the tank, the longer the compressor can run a tool before the motor kicks on.

The “gallon” refers to the size of the tank. This is like a battery. The bigger the volume of the tank, the longer the compressor can run a tool before the motor kicks on.

It arrived in a big crate, and I made quick work of uncrating it and moving it into it’s final position with a dolly and some grunting and shoving.

It arrived in a big crate, and I made quick work of uncrating it and moving it into it’s final position with a dolly and some grunting and shoving.

Raise your hand if you’ve ever lugged a heavy, noisy, vibrating string trimmer all over God’s green earth and then had a backache that evening.

Raise your hand if you’ve ever lugged a heavy, noisy, vibrating string trimmer all over God’s green earth and then had a backache that evening. They are really made for cutting acreage. And even then, depending on your terrain and what you’re trying to cut, they may not be suitable.

They are really made for cutting acreage. And even then, depending on your terrain and what you’re trying to cut, they may not be suitable.

If you’re a regular reader of ChainsawsToday, you know I love getting my hands on various chainsaws and trying them out.

If you’re a regular reader of ChainsawsToday, you know I love getting my hands on various chainsaws and trying them out.

Or maybe you live on a tropical island and you don’t even own a winter coat!

Or maybe you live on a tropical island and you don’t even own a winter coat!

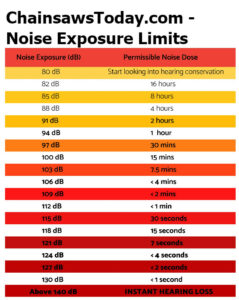

In many cases, once it’s lost, it never comes back. Also, it can be cumulative. The more exposure you have to loud noise, over time it will absolutely begin to affect your hearing.

In many cases, once it’s lost, it never comes back. Also, it can be cumulative. The more exposure you have to loud noise, over time it will absolutely begin to affect your hearing.

Right out of the box, this thing started right up and gave me no issues cutting.

Right out of the box, this thing started right up and gave me no issues cutting.

This thing starts easily. I have heard some folks complaining about getting it started, but I often wonder if those are people that complain about starting all saws. I had no trouble hot or cold, a few pulls of the cord and it was rip-roaring.

This thing starts easily. I have heard some folks complaining about getting it started, but I often wonder if those are people that complain about starting all saws. I had no trouble hot or cold, a few pulls of the cord and it was rip-roaring.